What are the key elements of dry distribution transformer technical conditions?

Time:2024-10-8 Auther:ZTelec-www.ztelectransformer.com

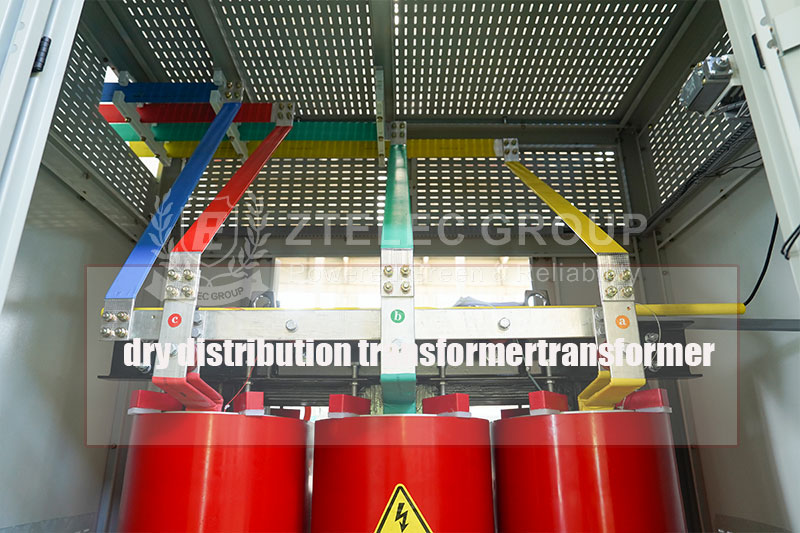

In modern power systems, dry-type distribution transformers have gradually become an essential component of electrical distribution facilities due to their excellent performance and diverse applications. Dry-type transformers are widely used in urban and industrial power consumption due to their safety, environmental friendliness, and compact structure. This article will discuss the key technical specifications of dry-type distribution transformers and how these specifications affect their practical applications and performance.

Ⅰ、Rated Parameters of the Transformer

The rated parameters of dry-type distribution transformers are fundamental to their design and application. These parameters typically include:

- Rated Power: The rated power of a dry-type transformer needs to be reasonably selected based on demand, with common rated power ranging from a few kilowatts to several megawatts. When selecting the transformer, it is essential to consider the maximum load and the potential for future load growth.

- Rated Voltage: It is crucial to choose the appropriate rated voltage for the transformer based on the operating voltage of the electrical equipment to ensure optimal operational performance.

- Rated Frequency: Transformers are generally designed for frequencies of 50Hz or 60Hz, with the specific choice depending on the frequency of the regional power grid.

Ⅱ、Insulation System

The insulation system is one of the most critical parts of dry-type distribution transformers, directly related to the safety and reliability of the transformers. Dry-type transformers use dry insulation materials such as epoxy resin or polyester, which have high insulation ratings, typically Class A or Class F. The selection of insulation materials aims to:

- Enhance Thermal Stability: The thermal performance of insulation materials should withstand both long-term and short-term temperature variations to avoid insulation failure under high-temperature conditions.

- Improve Weather Resistance: In harsh environments (such as high humidity, high temperatures, and salt fog conditions), insulation materials must possess good corrosion resistance and moisture-proof characteristics.

- Ensure Reliability: The thickness of the insulation layer and the quality of the materials directly impact the electrical strength and lifespan of the transformers, so stringent controls should be applied during the design phase according to relevant standards.

Ⅲ、Heat Dissipation Performance

Dry-type distribution transformers generate a significant amount of heat during operation, making effective heat dissipation design crucial. Key elements of heat dissipation performance include:

- Temperature Rise Limit: The temperature rise should be designed reasonably based on the rated power of the transformer and the ambient temperature, ensuring operation within specified limits.

- Cooling Methods: Common cooling methods include natural ventilation and forced ventilation. Natural ventilation is suitable for small transformers, while forced ventilation can be applied to high-power or high-density transformers.

- Cooling Materials: The heat resistance of the materials used for the transformer enclosure and internal components must be good to maintain mechanical strength and insulation performance during high-temperature operation.

Ⅳ、Mechanical Strength

The mechanical strength of dry-type transformers is one of the important factors ensuring their stable operation over extended periods. Key aspects include:

- Structural Design: The design of the transformer structure needs to have sufficient strength to withstand various mechanical stresses during transportation, installation, and potential vibrations during operation.

- Material Selection: High-strength metal materials and wear-resistant non-metal materials are indispensable in transformer manufacturing to ensure a long service life.

- Seismic Performance: In areas prone to earthquakes, the seismic design of dry-type transformers must be enhanced to prevent damage due to seismic activity.

Ⅴ、Environmental Adaptability

With the increasing requirements for environmental protection, dry-type distribution transformers must demonstrate excellent environmental adaptability. Key areas of focus include:

- Water and Moisture Resistance: In high-humidity or rainy environments, the design for water and moisture protection of the transformer is crucial to ensure that its insulation performance is not compromised.

- Corrosion Resistance: For special environments such as chemical or marine settings, choosing corrosion-resistant materials and coatings will help extend the lifespan of the transformer.

- Low Noise Design: Modern dry-type transformers must consider noise control to meet the requirements of urban environments and residential living.

Ⅵ、Maintenance and Management

The long-term stable operation of dry-type distribution transformers relies on effective maintenance and management. Key aspects include:

- Regular Testing: Establishing a comprehensive testing mechanism to regularly check important indicators such as insulation performance, temperature rise, and load enables timely detection and resolution of problems.

- Documentation and Analysis: Detailed documentation and analysis of data during transformer operation can provide reliable insights into the operational status of the equipment.

- Technical Training: Regular professional training for maintenance personnel is essential to ensure they are familiar with the operation, fault handling, and maintenance knowledge of dry-type transformers.

The key technical specifications of dry-type distribution transformers are not only related to their design and manufacturing but also directly affect their performance in practical applications. By accurately understanding and grasping these technical elements, we can better promote the advancement and application of dry-type transformer technology, enhancing their importance and reliability in power systems. In future electrical construction, dry-type distribution transformers will continue to play an irreplaceable role.