Dry Type Transformer Maintenance Guide

Time:2024-11-19 Auther:ZTelec-www.ztelectransformer.com

Dry Type Transformers are indispensable equipment in power systems, increasingly used in various power facilities due to their superior insulation materials and good heat dissipation performance. Compared to oil-immersed transformers, Dry Type Transformers offer higher safety, environmental friendliness, and adaptability, making them particularly advantageous in situations with high fire safety and environmental protection requirements. However, despite their long service life, regular maintenance and inspection are crucial to ensure their optimal operating condition and continuous power supply capability. This article aims to provide a systematic maintenance guide for Dry Type Transformers, helping relevant personnel effectively extend the equipment’s lifespan and improve operational reliability.

Structure and Operating Principle of Dry Type Transformers

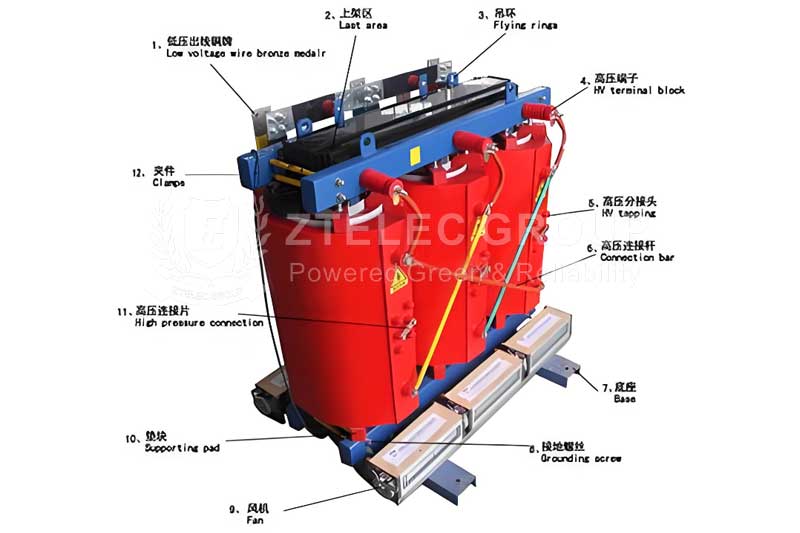

The basic structure of a Dry Type Transformer mainly includes the core, windings, and insulation materials. The core is typically made of high-permeability silicon steel sheets, which effectively reduce energy loss through its magnetic pathway; the windings consist of conductors wrapped in multiple layers of insulation materials, with the design of the windings being key to ensuring the transformer operates efficiently. Additionally, the insulation materials used in Dry Type Transformers are often new composite materials like epoxy resin, which not only provide excellent insulation performance but can also withstand higher temperatures.

During operation, Dry Type Transformers convert high voltage to low voltage or vice versa through the principle of electromagnetic induction. As current flows through the windings, a magnetic field is generated in the core, which in turn adjusts the ratio of voltage to current. The heat dissipation mechanism of Dry Type Transformers primarily relies on their open structure and the heat exchange process with the surrounding air. When the transformer is overloaded, the heat generation increases, making effective heat dissipation critical for its normal operation.

Daily Maintenance Key Points

1. Appearance Inspection

The appearance of a Dry Type Transformer is important, and regular surface checks can help identify potential issues promptly. Inspection items include:

– Checking for physical defects such as damage or cracks;

– Verifying the integrity of the insulation layer to ensure no foreign contaminants are present;

– Measuring surface temperature to ensure operating temperatures are within the specified range;

– Inspecting protective devices (such as dust covers) for completeness and effectiveness.

2. Cleaning and Maintenance

Cleaning maintenance of Dry Type Transformers includes the following:

– Regularly removing dust and dirt from the transformer’s surface to maintain good ventilation;

– Checking air intake and outlet ports to ensure they are free of obstructions;

– Performing localized cleaning on components prone to dust accumulation and increasing cleaning frequency.

3. Temperature Monitoring

The rise in temperature during the operation of Dry Type Transformers is a significant factor affecting their lifespan. Therefore, temperature monitoring is particularly important:

– Installing temperature monitoring devices to record the transformer’s operating temperature in real-time;

– Checking temperature records weekly to analyze temperature trends;

– Taking timely cooling measures when temperatures exceed the design range, and reducing the load if necessary.

4. Electrical Testing

Electrical testing mainly includes the following aspects:

– Regularly conducting insulation resistance tests to ensure good insulation performance;

– Performing turns ratio tests and short-circuit impedance tests on the transformer to check if its electrical parameters meet design specifications;

– Checking the grounding of the windings to ensure reliable grounding.

5. Fault Diagnosis

During operation, if any abnormalities such as noise or overheating are detected, immediate fault diagnosis should be performed:

– First, shut down the transformer to ensure safe operation;

– Carefully inspect all components to locate the source of the fault;

– Based on the type and severity of the fault, develop corresponding corrective measures.

Maintenance Records and Management

To ensure the maintenance process of Dry Type Transformers is orderly, detailed maintenance records should be established. Maintenance records should include:

– Inspection records of daily maintenance;

– Results and analyses of various tests;

– Fault situations and handling measures;

– Records of repairs or component replacements.

Through these records, a systematic analysis of the Dry Type Transformer’s operational status can be conducted, allowing for timely adjustments to maintenance strategies and the prevention of potential risks.

As important equipment in modern power systems, the reliability of Dry Type Transformers directly affects the stable supply of electricity. Conducting systematic maintenance not only effectively extends the equipment’s service life but also enhances the safety and reliability of the entire power system. Therefore, by following the maintenance guide provided in this article, relevant personnel can better master maintenance techniques, ensuring the Dry Type Transformer operates in excellent condition and safeguarding the normal operation of power facilities.