Copper core transformer

Copper core transformer product description: Ztelec is specialized in producing copper core transformer, dry type, oil type transformer, American and European box transformer with a capacity from 30 kva to 31500 kva. Copper core transformer has cha……

Copper core transformer product description:

Ztelec is specialized in producing copper core transformer, dry type, oil type transformer, American and European box transformer with a capacity from 30 kva to 31500 kva. Copper core transformer has characteristics of low loss, obviously energy saving effect, and maintenance free. And it has trait of high efficiency, low operating cost, short circuit resistance. The transformers produced by ztelec are of good quality and have a long service life. The shelf life can last up to 3 years. Meanwhile Ztelec is a professional manufacture, it is support to customized transformers according to customer needs.

Copper core transformer production video:

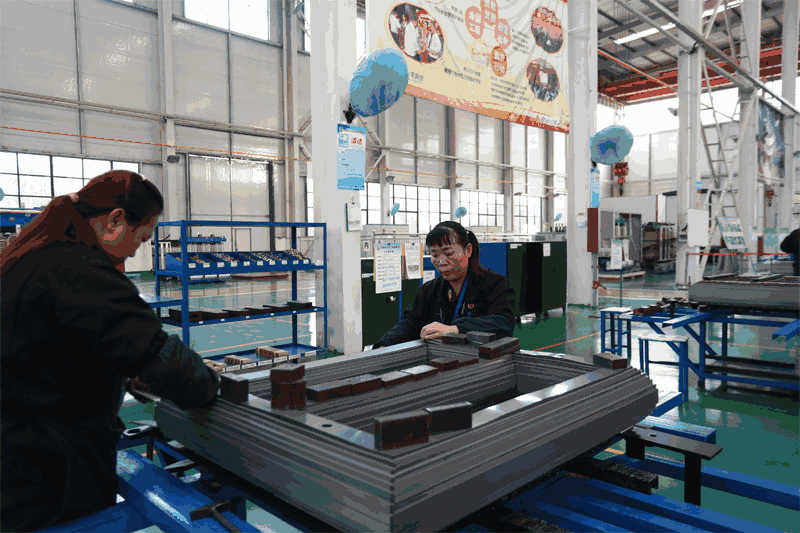

Record each Copper core transformer production process, from material selection to transportation.

Copper core transformer parameter:

| Type | Rated Capacity | HV | LV | Connection Group | Short Circuit Resistance | No Load Loss | Load Loss 120℃ | No Load Current |

| (KVA) | (KV) | (KV) | (%) | (W) | (W) | (%) | ||

| Dry and Oil Type | 30 | 6 6.3 10 10.5 11 20 22 24 30 33 35 38.5 |

0.4 | Dyn11

Yyn0 |

6 | 380 | 1210 | 3.2 |

| 63 | 520 | 1550 | 2.6 | |||||

| 100 | 630 | 2090 | 2.4 | |||||

| 125 | 710 | 2450 | 2.2 | |||||

| 200 | 880 | 3330 | 1.8 | |||||

| 250 | 990 | 3800 | 1.6 | |||||

| 400 | 1380 | 5420 | 1.4 | |||||

| 500 | 1620 | 6650 | 1.4 | |||||

| 800 | 2160 | 9120 | 1.2 | |||||

| 1250 | 2840 | 12730 | 0.9 | |||||

| 2000 | 3830 | 18240 | 0.9 | |||||

| 2500 | 4460 | 24850 | 0.9 | |||||

| Oil Type | 3150-6300 | 35-38.5 | 3.15-10.5 | Yd11 | 43562 | 3040-5250 | 23090-35060 | 1.5-0.8 |

| 8000-31500 | 3.15-11 | Ynd11 | 43654 | 7200-20220 | 38480-112800 | 0.54-0.32 |

Copper core transformer Production Display:

The silicon steel sheets purchased by ztelec are all high-quality products, which can reduce the iron loss of the manufactured

Copper core transformer’s detection and testing equipment:

Ztelec insists on testing every part to make sure the quality of every product. And each transformer is tested by our professional team. Guarantee the safety of our product.

Copper core transformer Packing and shipping:

In order to ensure that each transformer can be protected from secondary pollution after production, we will put a moisture-proof dust bag on it. Then the transformer will be transported to a constant temperature and moisture-proof warehouse for storage.For the safety of transformer transportation, we first pour out the transformer oil in the transformer and then prevent the transformer from being inside the dust proof and waterproof membrane. Fix the base of the transformer and put on a customized wooden box.

Copper core transformer’s advantages:

1. High strength: Allowable stress at room temperature, copper is 7~28% higher than aluminum. Especially the stress at high temperatures, the difference between the two is even more distant.

2. Anti-fatigue: Aluminum is easy to break under repeated bending, and copper is not easy. In terms of elasticity, copper is also about 1.7 to 1.8 times higher than aluminum.

3. Convenient construction: 1 The copper core is flexible, and the allowable bending radius is small, so the turning is convenient and the pipe is easy to wear; 2 the copper core is anti-fatigue, repeated bending is not easy to break, so the wiring is convenient; 3 the mechanical strength of the copper core is high, Can withstand large mechanical tension, bring great convenience to construction, and also create conditions for mechanized construction.

4. Good stability, corrosion resistance: The copper core is resistant to oxidation and corrosion, and the aluminum core is susceptible to oxidation and corrosion.

Copper core transformer certificate:

Established in 1958, ztelec has a complete production system and first-class production equipment. To ensure the quality of each product, we have produced a Copper core transformer test report.